Description

Flexible Foam Insulation in Nepal

Flexible Foam Insulation 1 Polyolefin Foam Insulation

Using flexible foam insulation in prefab houses in Nepal can be a practical choice given the country’s climatic conditions and the need for energy efficiency. Here’s how you might approach it:

1. **Research and Select Suitable Insulation**: Look for flexible foam insulation options that are suitable for the Nepalese climate. Consider factors such as thermal resistance (R-value), moisture resistance, fire resistance, and availability in the local market.

2. **Prefab House Design**: Ensure that the design of the prefab house accommodates the installation of flexible foam insulation. This might involve incorporating cavities or spaces within the walls and ceilings where the insulation can be placed.

3. **Supplier Selection**: Identify suppliers or manufacturers who can provide the required quantity of flexible foam insulation. Consider factors such as cost, quality, and delivery logistics, especially considering the remote areas of Nepal where transportation might be a challenge.

4. **Installation Process**: Work with experienced contractors who understand how to install flexible foam insulation properly. Proper installation is crucial for maximizing its effectiveness in providing thermal insulation and energy efficiency.

5. **Regulatory Compliance**: Ensure that the selected insulation material meets local building codes and regulations in Nepal. This might involve certifications or approvals from relevant authorities.

6. **Consider Environmental Impact**: Evaluate the environmental impact of the chosen insulation material. Look for options that are eco-friendly and have minimal long-term effects on the environment.

7. **Maintenance and Durability**: Choose insulation materials that are durable and require minimal maintenance over time. This will help ensure the longevity and effectiveness of the insulation in the prefab house.

8. **Cost Consideration**: While flexible foam insulation can offer excellent thermal performance, it’s essential to consider the overall cost-effectiveness of the solution, including both initial installation costs and long-term energy savings.

9. **Educate End Users**: Provide guidance and information to the occupants of the prefab houses about the benefits of flexible foam insulation and how to maintain it properly to maximize its effectiveness.

By carefully considering these factors and integrating flexible foam insulation into the prefab house design and construction process, you can create energy-efficient and comfortable living spaces in Nepal.

Product Details:

`Polyolefin is general term used for compound of olefin as a monomer. Polyolefin foams are composed of several materials that have been mix together to form a compound structure. Basically these are organic blowing agent and crosslink agent mixed together to form polyolefin Resin.

1.1 XLPE Sheets & Tubings

Product Details:

XLPE is Chemically cross link polyethylene, which is monomer of ethylene olefin. XLPE is Closed cell fire retardant polyethylene foam used for much insulation application. It is available in both Sheet and Tube form.

It is also available with facing of Aluminum Foil, Fiber glass cloth or UV barrier

| Densities (Kg/M3) | 30 +/- 3 |

| Cell structure | Closed Cell |

| Pipe Diameter | ¼” to 4” ( 6 mm to 100 mm) |

| Thicknesses in (mm) | 6,9,13,19,25,32 (Tubes and Sheet) |

| Dimensions | 1.25 Mt W (varies from 10 Mts to 30 Mts ) |

| Temperature Range | -40 Deg C to 115 Deg C |

| Thermal Conductivity | 0.032 / 0.034/ 0.038 W/mk |

| USES: |

|

1.2 Acco Isolate Acoustic Insulation

Product Details:

Oxide Acetate Foam is chemically cross link Oxide accetate foam. AccoIsolate is an open cell structure Acoustic Insulation utilize for large acoustic application.

| Densities (Kg/M3) | 30 to 60 |

| Cell structure | Open Cell, Cross linked, Stress Crack resistant |

| Physical Appearance | One side Open Cell, Soft, Flexible and Glossy |

| Thicknesses in (mm) | 10,15,25,35 |

| Temperature Range | -70 Deg C to 100 Deg C |

| Thermal Conductivity | 0.029 W/ mk at 0 Deg C |

| USES: |

|

1.3 Oxide Acetate Sheets & Tubings

Product Details:

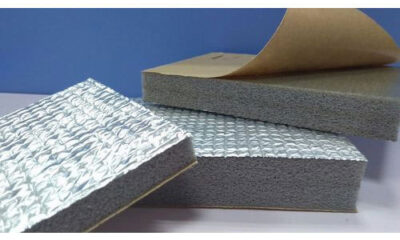

It is cross linked closed cell Oxide acetate foam used for thermal Insulation in AC ducting, Chilled water pipe, under deck/ over deck in RCC Roofing and metallic roofing This is UV resistive product also has Class “o” fire properties as per BS 476 part 6 material is also offered with factory laminated glass cloth and pure aluminum foil to give higher mechanical strength to the product.

| Densities (Kg/M3) | 30 +/- 3 |

| Cell structure | Closed Cell, Cross linked, Stress Crack resistant |

| Physical Appearance | Soft, Flexible and Glossy |

| Thicknesses in (mm) | 6,9,13,19,25,32 (Tubes and Sheet ) |

| Temperature Range | -70 Deg C to 100 Deg C |

| Thermal Conductivity | 0.029 W/ mk at 0 Deg C |

| USES: |

|

2 Elastomeric Rubber Insulation

Product Details:

Elestomeric Rubber are Polymer with viscoelasticity.

Elastomeric Nitrile Rubber ( NBR) is copolymer of acrylo-nitrile and butadiene. Nitrile Rubber is oil Resistant synthetic rubber. Its Physical and Chemical Property vary with different composition of Nitrile Polymer’s.

NBR is made in Hydrogenated version that is highly resistant to thermal and oxidative deterioration and remains flexible at lower Temp.

2.1 Nitrile Rubber Sheets & Tubing’s

Product Details:

Elastomeric foam Insulation material manufactured from Nitrile Rubber in Preformed tubing and sheet. Nitrile Rubber insulation shows various properties due to its close cell and open cell structure. Closed cell Nitrile Rubber insulation has good thermal property while open cell structure provide good acoustic properties. It can be bifurcated in Class “O” and Class “1” on the basis of its fire resistance properties.

| Densities (Kg/M3) | 40-60 |

| Thermal Conductivity | 0.038 at ambient |

| Thicknesses in (mm) | 6,9,13,19,25, 32 |

| Pipes diameter from | (¼” )6 mm to (4 ¼”) 108 mm (tube length 2 Mt) |

| Temperature Range | – 40 Deg C to +105 Deg C |

| USES: |

|

2.1.1 Accosound

Product Details:

Accosound is blended elastomeric Nitrile rubber open cell structure acoustic insulation foam with complex pore geometry for effective absorption of sound across broad range of frequencies.

Its high density provides effective barrier to sound transmission. (EPA Approved anti-microbial agent).

| Densities (Kg/M3) | 200 (+ or – 10% ) |

| Thicknesses in (mm) | 10, 12, 15 ,20,25,30 |

| Temperature Range | – 40 Deg C to +105 Deg C |

| USES: |

|

2.1.2 Accofoam

Product Details:

Accofoam is a thermo acoustic convoluted elastomeric Nitrile foam material provides superior sound absorption for low and mid frequency range. Its convoluted shape increase the absorptive surface area and it entraps and deflects sound waves efficiently.

Accofoam is an excellent choice for fire safe, flexible, light weight , high performance noise absorption material is required.

| Densities (Kg/M3) | 50 |

| Thermal Conductivity | ≤ 0.036 W/mk @ 20 Deg C |

| Thicknesses in (mm) | 9, 12, 15, 19 , 25 |

| Fire Safety | Class “O” |

| Advantages: |

|

3 EPDM Rubber Sheets & Tubing’s

Product Details:

Closed cell elastomeric foam insulation material manufactured from EPDM rubber in preformed tubing and sheet. It has low thermal conductivity and high water vapour diffusion resistance. It is free from HCFC and CFC. It is fiber free material and it ensures to save energy in eco friendly manner.

| Densities (Kg/M3) | 50 to 70 |

| Thicknesses in (mm) | 6,9,13,19,25, 32 |

| Pipe Diameter | (¼” ) 6 mm to (4 ¼”) 108 mm (tube length 2 Mt) |

| Temperature Range | – 50 Deg C to +125 Deg C |

| Thermal Conductivity | Varies from 0.031 to 0.037 at different temp. |

| USES: |

|

Reviews

There are no reviews yet.